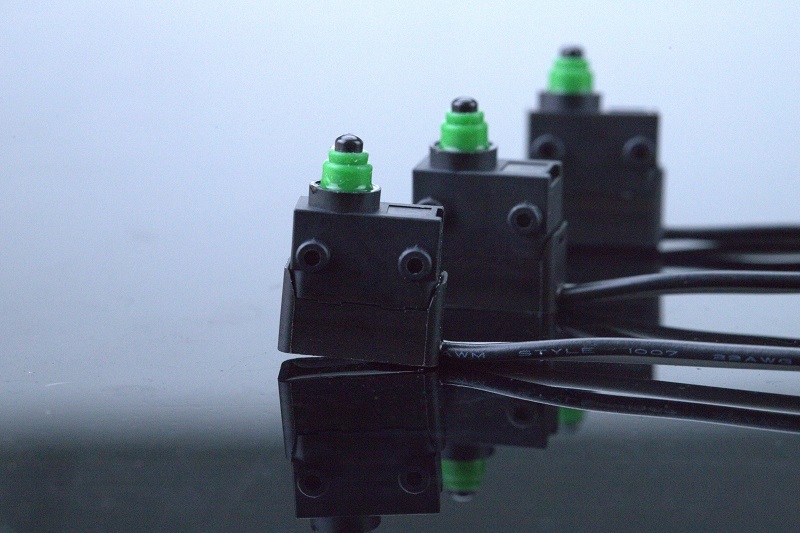

Waterproof micro switches are expected to “just work” in harsh environments — whether they are installed in automotive door locks, outdoor machinery, HVAC equipment, or DIY robotics projects. Yet real-world feedback from both hobbyists and industrial engineers shows that even IP-rated switches can fail prematurely if the right selection and integration practices are not followed.

This article distills the most common failure modes, why they happen, and what engineers can do to avoid them during design, assembly, and long-term use.

Typical symptoms:

Intermittent triggering, corrosion on terminals, or complete loss of actuation.

Why it happens:

Misalignment between the switch’s IP rating and the actual application environment

Improper mounting orientation causing water pooling

Over-tightening of screws deforming the sealing gasket

Use of incorrect seal boots or absence of external protection in splash zones

How to prevent it:

Match IP rating to real exposure (IP67 for full immersion, IP65/66 for jets)

Avoid mounting with the actuator facing upward

Use manufacturer-approved sealing accessories

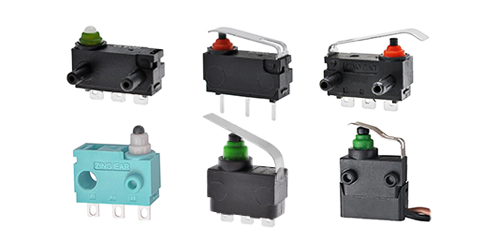

Select switches with proven sealing structures such as double-rubber boots, ultrasonic-welded housings, or reinforced O-rings

Typical symptoms:

Actuator becomes loose, requires excessive force, or fails to return to its neutral position.

Why it happens:

Over-travel beyond design limits

High-frequency cycling in industrial machines

Side-loading forces from misaligned cams or levers

Use of low-grade materials in DIY or low-cost replacements

How to prevent it:

Choose a switch with appropriate Operating Force (OF) and over-travel tolerance

Use models with metal actuators or reinforced hinge mechanisms for high duty cycles

Add mechanical guides to prevent side loads

Validate cycle life in accelerated testing — industrial applications often need >500k–1M cycles

Typical symptoms:

Increased contact resistance, burnt smell, sporadic actuation under vibration.

Why it happens:

Exposure to moisture or chemicals despite IP sealing

Incorrect terminal plating for the environment

Use of non-sealed connectors or bare wires in humid zones

DIY users often skip proper insulation and strain relief

How to prevent it:

Select terminals with silver alloy, gold plating, or anti-oxidation materials depending on load

Use sealed connectors, conformal coating, or heat-shrink tubing

Consider waterproof switches with independent terminal chambers to isolate moisture

Follow correct torque specifications for terminal screws

Typical symptoms:

Burnt contacts, welded contacts, or sudden switch death.

Why it happens:

Load exceeds the switch's amp rating

Inrush current spikes from inductive loads (motors, solenoids)

Using a DC-rated switch in an AC application or vice versa

DIY users often underestimate the need for surge suppression

How to prevent it:

Always calculate steady-state + inrush current

Add RC snubbers, varistors, or diodes for inductive loads

Never downgrade IP-rated switches with non-approved cable modifications

Select switches with appropriate electrical endurance certifications (UL, ENEC, CQC, etc.)

Typical symptoms:

Delayed actuation, rubber boot cracking, or reduced contact force.

Why it happens:

Extreme ambient temperatures beyond spec

Thermal expansion affecting actuator geometry

Low-quality elastomers degrading in cold or hot environments

How to prevent it:

Match the switch’s operating temperature range to real conditions

Use models with high-temperature silicone boots or engineering-grade plastics

Validate performance under thermal shock testing

Keep switches away from heat sources like motors or headlights

Typical symptoms:

Contact bounce, inconsistent output, internal spring deformation.

Why it happens:

Mounted directly on vibrating structures

No damping or isolation

Long levers amplifying vibration forces

How to prevent it:

Use compact snap-action designs with short actuators

Add rubber isolation pads or mount to stable surfaces

Choose automotive-grade switches tested for vibration, drop, and shock

| Users | Common Mistakes | Key Takeaway |

|---|---|---|

| DIY Makers | Using oversized loads, skipping sealing accessories, mounting in exposed orientations | Waterproof ≠ indestructible — correct installation matters |

| Industrial Engineers | Underestimating vibration, chemical exposure, and real operating cycles | Specify conservatively; consider worst-case load and environment |

| Automotive/OEM | Focusing on IP rating but ignoring mechanical integration | System-level sealing and mounting define real durability |

A robust waterproof micro switch should ideally offer:

Certified sealing (IP67/IP68 or customer-specific validation)

Global safety certifications (UL, cUL, ENEC, CQC)

Reinforced housing and actuator structure

Long mechanical life and repeatable snap-action

Material compatibility for humidity, chemicals, oils, and temperature extremes

Unionwell’s automotive-grade waterproof micro switch families are designed around these principles, including optimized sealing architecture and high cycle life for demanding environments.

Waterproof micro switch failures often stem not from the switch itself, but from mismatched application requirements, improper installation, or environmental extremes. By understanding these common failure points — and designing around them — engineers can significantly extend switch life and ensure consistent performance in both DIY and industrial applications.

If you need support selecting a waterproof micro switch for a specific automotive, machinery, or outdoor-use scenario, I can help you refine your specification and recommend the most suitable Unionwell models.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  português

português  tiếng việt

tiếng việt  Türkçe

Türkçe  slovenský

slovenský  slovenčina

slovenčina  беларускі

беларускі .webp)